Ultimate Way to Manage Your Fleet

MiLVUS Fleet Manager is an advanced fleet management software designed to streamline autonomous mobile robot (AMR) operations across North American warehouses, manufacturing plants, and logistics centers. Milvus Fleet Manager provides real-time monitoring, task management, and seamless systetion, ensuring efficiency and scalability in material handling workflows.

Real-time Fleet Monitoring

MiLVUS Fleet Manager provides live tracking, instant status updates, and remote diagnostics to ensure seamless AMR operations.

Smart Task & Traffic Management

AI-driven task allocation, dynamic path planning, and intelligent scheduling optimize workflow efficiency and prevent congestion.

Seamless System Integration

With standard APIs and compatibility with WMS, ERP, and MES systems, it enables effortless integration into existing automation ecosystems.

Data-Driven Insights & Analytics

Advanced dashboards, predictive analytics, and customizable reports empower data-driven decision-making for continuous optimization.

Fleet Manager

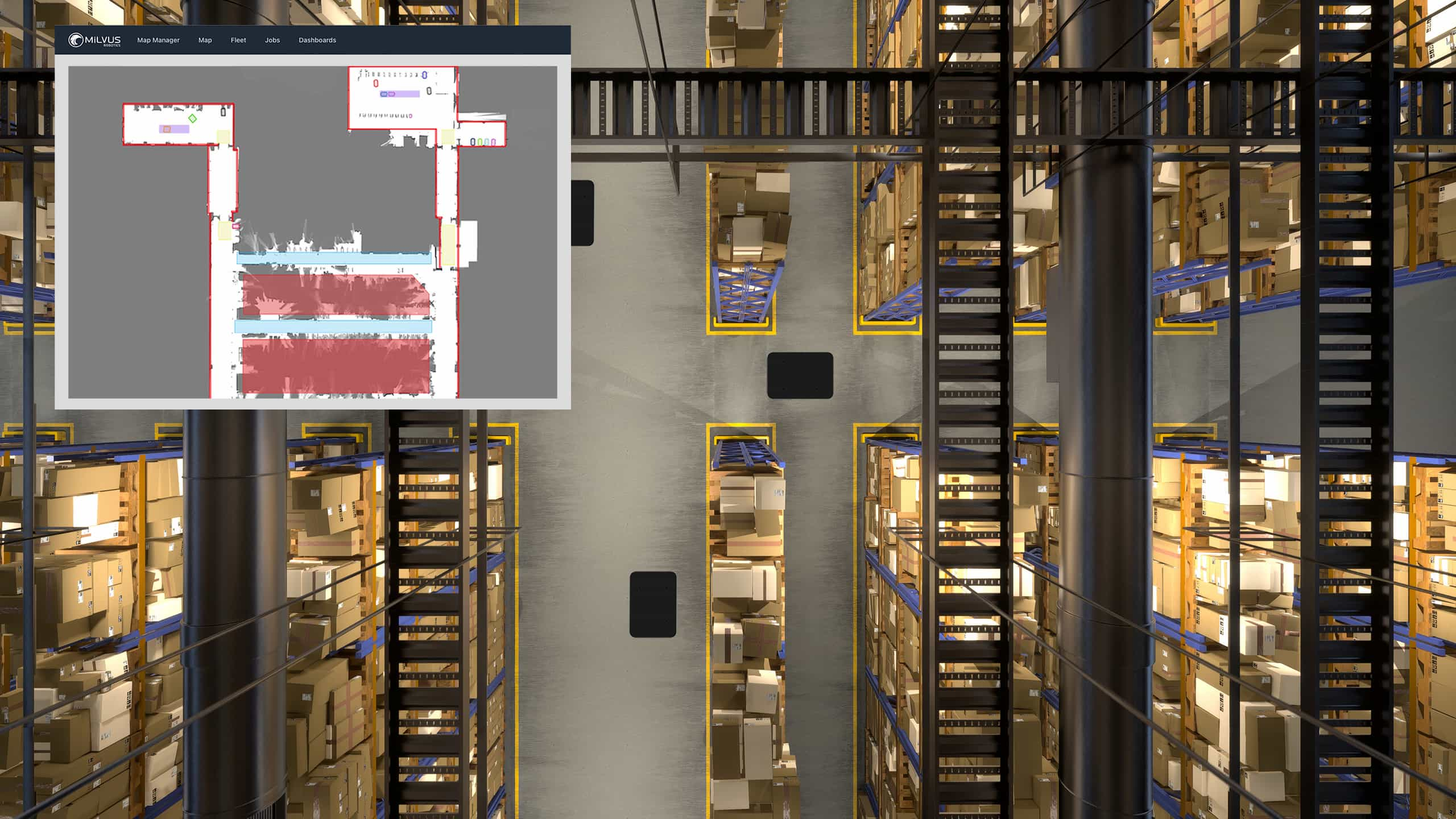

Real-Time Fleet Monitoring

Stay in control of your AMR operations with real-time visibility and instant insights.

Live tracking of all AMRs with interactive maps. Monitor every robot’s movement in real time through an intuitive interface, ensuring full operational awareness.

Instant status updates and performance insights. Stay informed with real-time status alerts and key performance indicators to optimize fleet efficiency.

Remote diagnostics and issue resolution. Identify and resolve issues proactively with remote access to diagnostic data, reducing downtime and maintenance costs.

Smart Task & Traffic Management

Optimize workflow efficiency with intelligent task distribution and adaptive traffic control.

AI-powered task allocation for optimal efficiency. Automatically assign tasks based on priority, load capacity, and real-time fleet availability.

Dynamic path planning to prevent congestion. Optimize robot navigation with adaptive routing that prevents collisions and streamlines movement.

Intelligent job prioritization and scheduling. Ensure time-sensitive tasks are completed efficiently with smart scheduling and workload balancing.

Seamless System Integration

Ensure a smooth transition into automation with flexible and scalable integration capabilities.

Compatible with WMS, ERP, and MES systems. Connect seamlessly with major warehouse and enterprise management platforms for unified operations.

Standard APIs for easy third-party software connection. Enable smooth communication between AMRs and other automation systems with flexible API support.

Scalable architecture for growing automation needs. Expand your fleet and automation capabilities effortlessly with a future-ready, modular software structure.

.webp)

Data-Driven Insights & Analytics

Unlock the full potential of your fleet with actionable data and performance insights.

Performance dashboards with key operational metrics. Access real-time data on fleet utilization, productivity, and efficiency in a user-friendly dashboard.

Predictive analytics for maintenance and optimization. Reduce downtime with AI-driven predictive maintenance that detects potential issues before they occur.

Customizable reports for continuous improvement. Generate detailed reports tailored to your operational needs, helping drive efficiency and cost savings.

.avif)