Company News

Explore Milvus Robotics' latest insights, case studies, and news on autonomous mobile robots (AMRs). Stay ahead with industry trends, expert articles, and real-world success stories.

Milvus Robotics Raises Series A Funding to $5.5 Million

Milvus Robotics announced that its Series A funding round has extended to USD 5.5 million following a strategic investment by Ak Portföy Venture Capit

Milvus Robotics Secures 4.5 Million Funding to Accelerate Global Expansion

Milvus Robotics, autonomous mobile robot (AMR) company, announced today the successful completion of a $4.5 million fund

Milvus Robotics Secures its Initial Investment to Drive Next Phase of Growth

Milvus Robotics, a rapidly growing autonomous mobile robot (AMR) company specializing in intralogistics for factories an

Milvus Robotics joins Ericsson Enterprise Partner Program in the Industry 4.0 track for Device and Hardware Partners

Milvus Robotics announced today that it has executed the required agreement to participate in Ericsson Enterprise partne

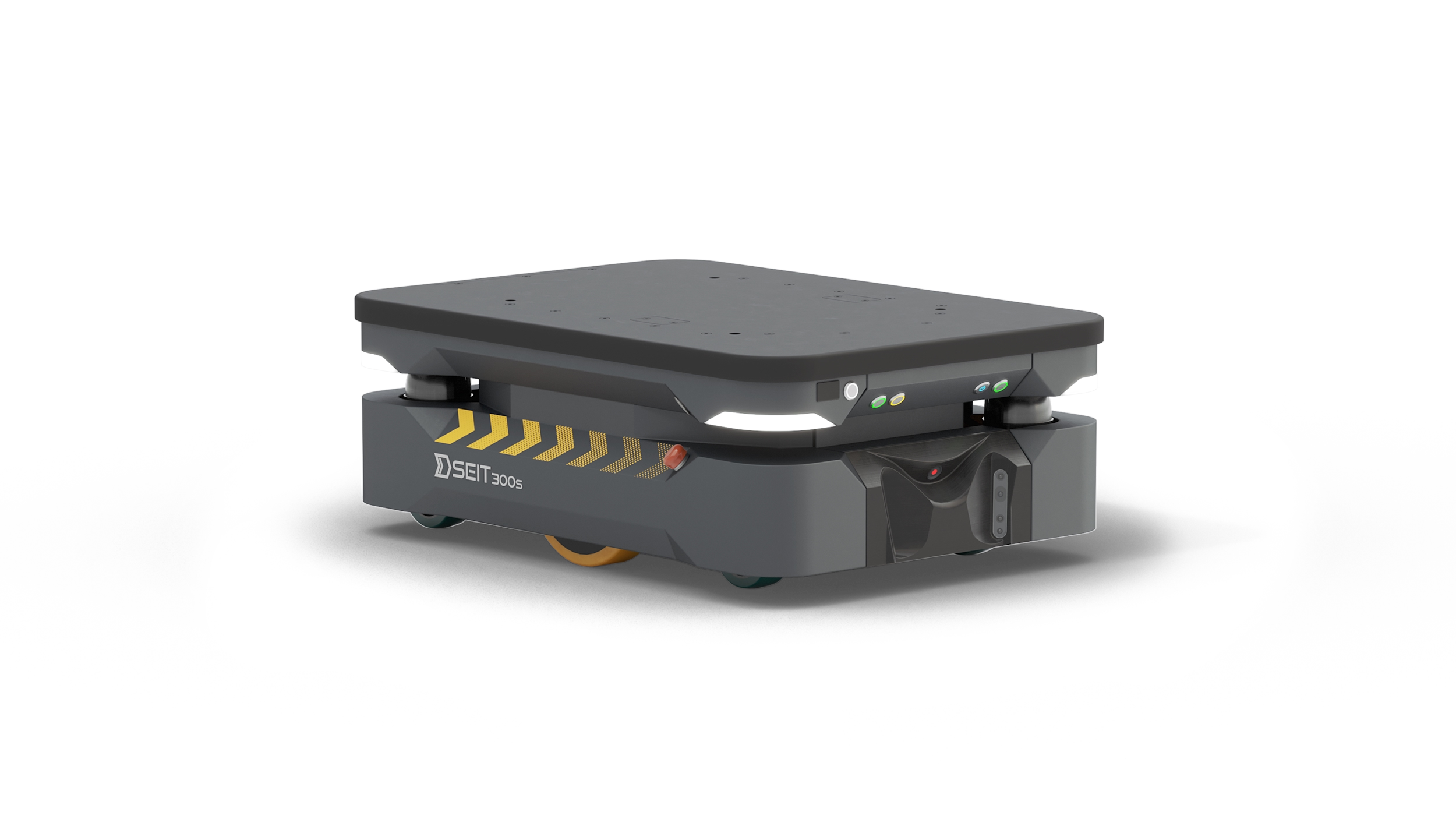

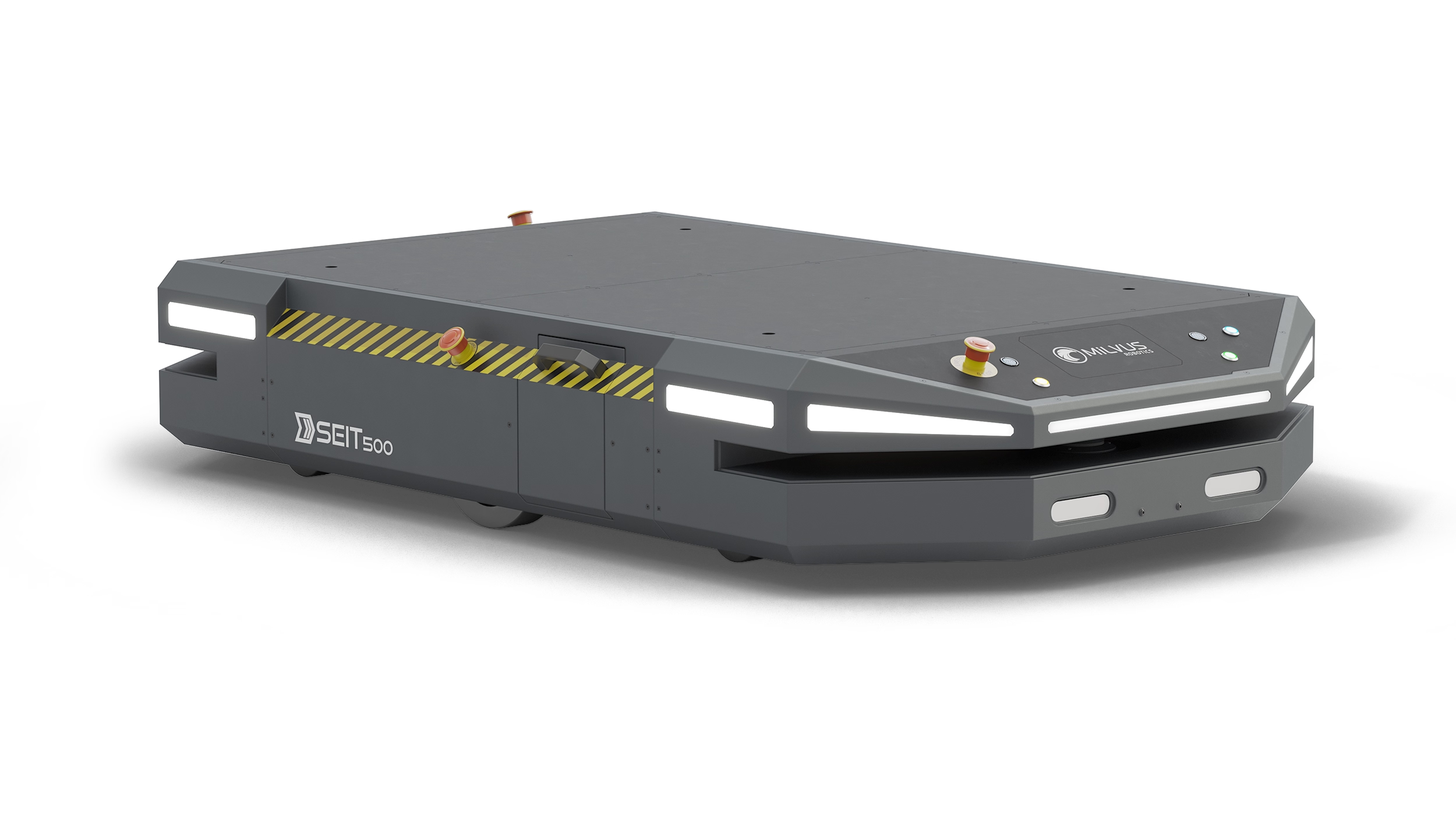

Milvus Robotics Introduces New Series as The Safest AMRs on The Market

With extended safety features and increased navigational performance, the new SEIT500-S and SEIT1500-S autonomous mobile

Milvus Robotics Celebrates 10th Year in Business

Milvus Robotics is pleased to announce and celebrate our 10th year in business. Thank you for an incredible decade – an

.avif)

-(1200-x-628-piksel).jpg)