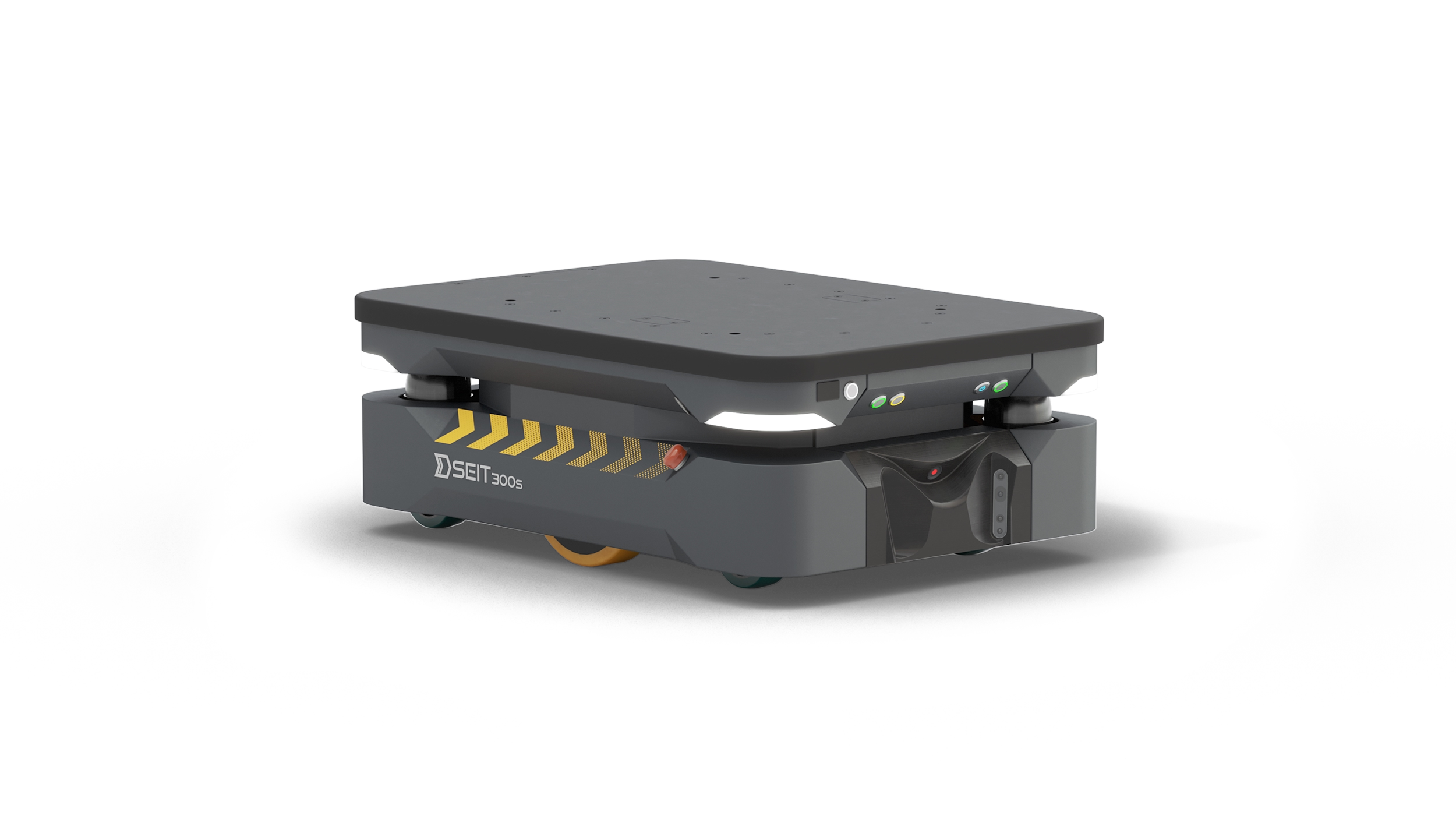

Agile And Dynamic AMR for Medium-Duty Applications

The SEIT300S is a versatile autonomous mobile robot designed for medium-duty material handling tasks. With advanced navigation and scalable fleet integration, it ensures efficient workflows. Perfect for industries requiring reliable automation, it optimizes warehouse and production operations.

- Payload 350 kg 772 lbs

- Working hour 10 hours 10 hours

- Max. speed 2 m/s 4.47 mph

- Dimensions 815 x 580 x 297 mm 32.1 x 22.8 x 11.7 in

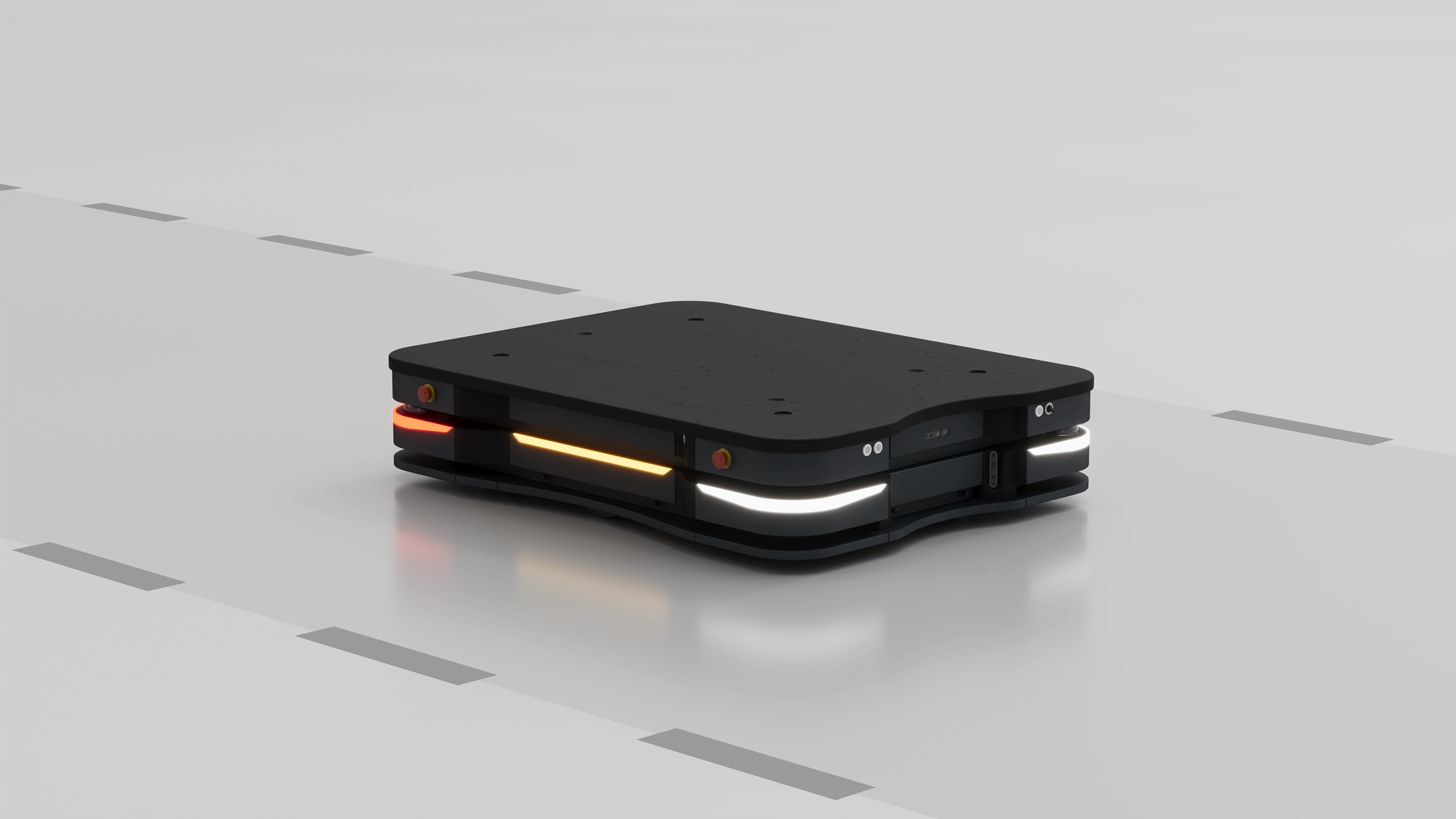

Infrastructure Free

SEIT300S navigates your facility without requiring physical infrastructure like magnets or beacons, ensuring no disruption to operations and reducing both initial setup and future maintenance costs.

High Precision

SEIT300S delivers exact precision, ensuring tasks are executed on time, consistently, and accurately. This reduces downtime and operational costs while improving productivity.

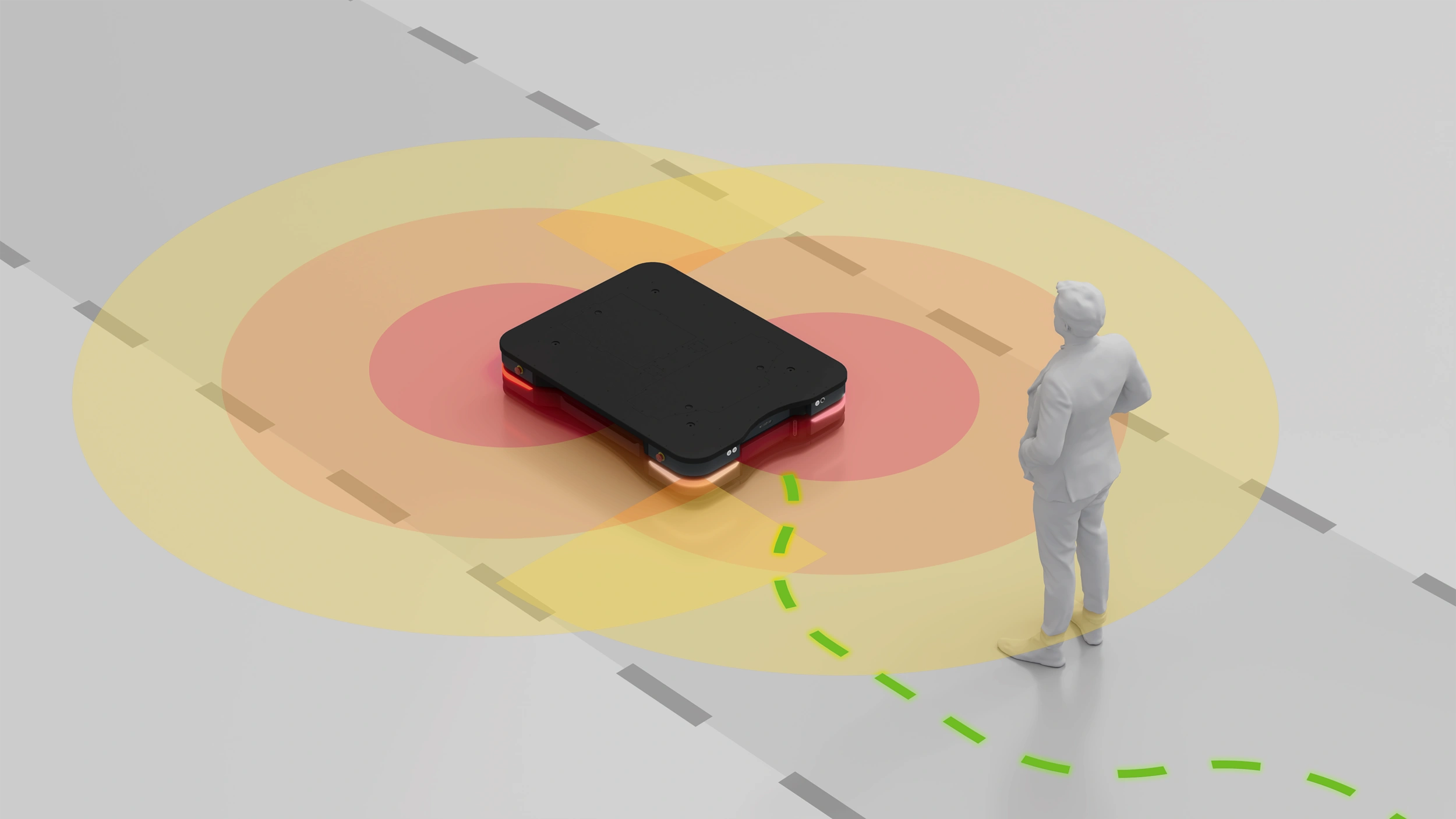

Enhanced Safety

Compliant with international safety standards, SEIT300S’ proactive sensing prevents accidents, minimizing injuries and related costs, ensuring a safer work environment.

Optimized Efficiency

SEIT300S reduces non-value-added transportation tasks, streamlining material movement for consistent delivery and allowing workforce reallocation to higher-value tasks.

Built for Durability

SEIT300S handles heavy loads up to 2000 kg and operates in challenging conditions. Its durable design and low maintenance components ensure long-term reliability and cost savings.

Milvus Fleet Manager

Manage Your Fleet, Maximize Your Efficiency

DiscoverMaximize efficiency and control over your AMR fleet with Milvus Fleet Manager, the leading solution for modern fleet management. Accessible from anywhere, this powerful system offers comprehensive tools for optimizing performance and coordinating your robots effortlessly. Elevate your operations with unmatched oversight and convenience.

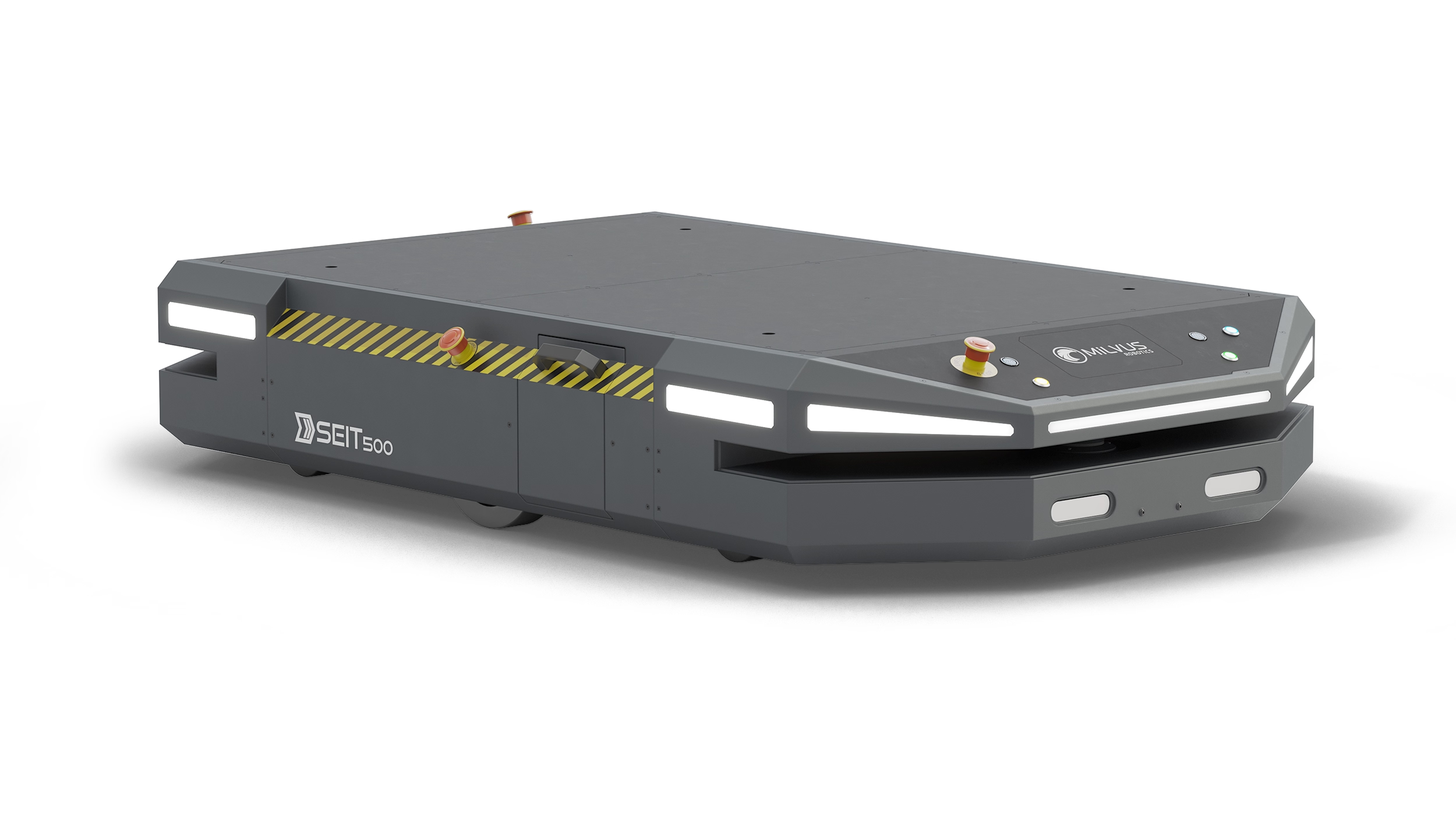

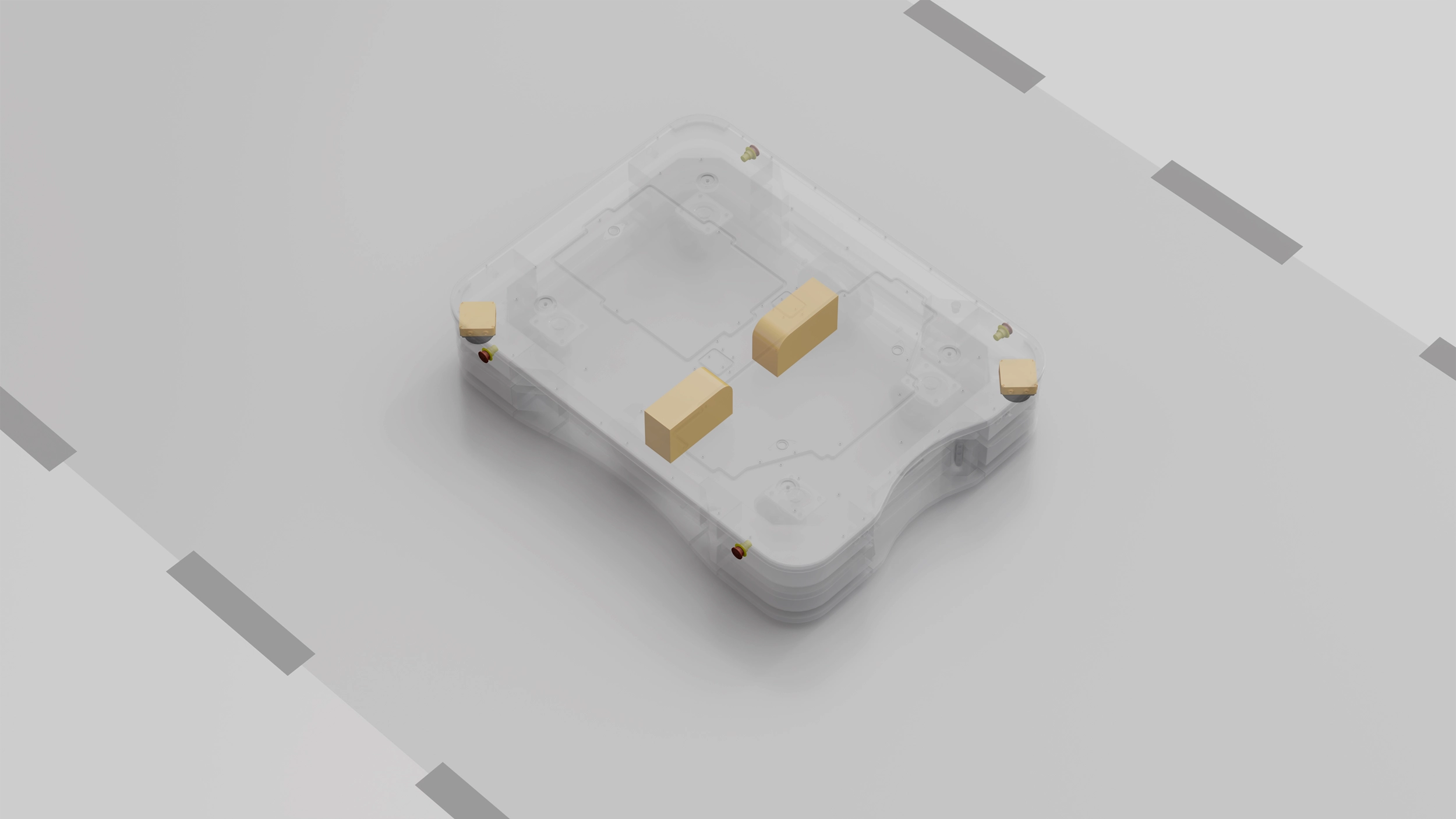

Attachments

Customize your AMR to your workflow

Milvus attachments turn the SEIT1500S into a versatile workhorse, whether you're lifting pallets, handling carts, or automating conveyors.

Safety

Engineered to thrive in dynamic workspaces

Equipped with emergency stop buttons, LiDAR sensors, and safety-rated brakes to meet industrial safety standards and certifications.

.avif)