How Autonomous Mobile Robots Help Create a Safer Workplace

Autonomous Mobile Robots

Safety is a top priority for manufacturing companies. After all, manufacturing and production workers have some of the most dangerous jobs as far as fatality rates go. Implementing AMRs in your operation is one way you can enhance safety for your employees and your facility. Here’s how.

Create a Safer Factory Floor

The more heavy-duty machinery you have moving around the production area, the more hazards there are present. For example, if you have multiple employees operating forklifts in your warehouse, each one presents a safety hazard. Even when you’re taking all the necessary precautions, accidents still happen.

The safer alternative is to deploy mobile robots to transport materials and parts from one area to another and dispose of materials as needed. Mobile robots work autonomously and efficiently. They are able to safely maneuver through the production area. These robots can perform the same duties as a forklift but while taking up less space. This leaves more room in the production area for employees to move freely and without obstruction.

Reduce Injuries from Material Transport

Manual laborers are especially vulnerable to developing strains and sprains on the job. This is especially true for employees that are constantly transporting heavy materials, even across short distances. All this heavy lifting takes a toll on the body. OSHA reports that materials handling is actually the number one reason American workers file workers comp claims. These injuries most commonly affect the back.

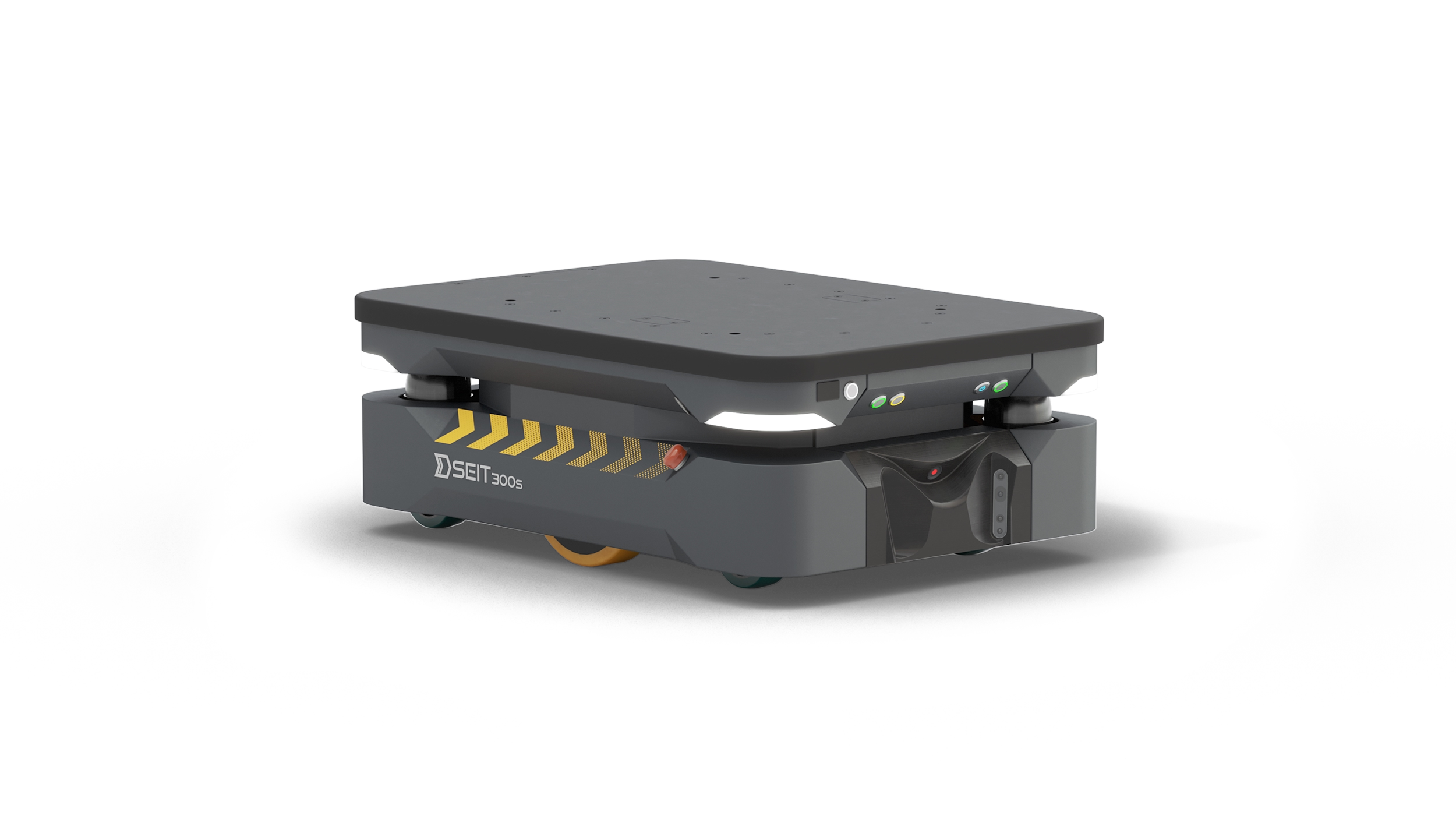

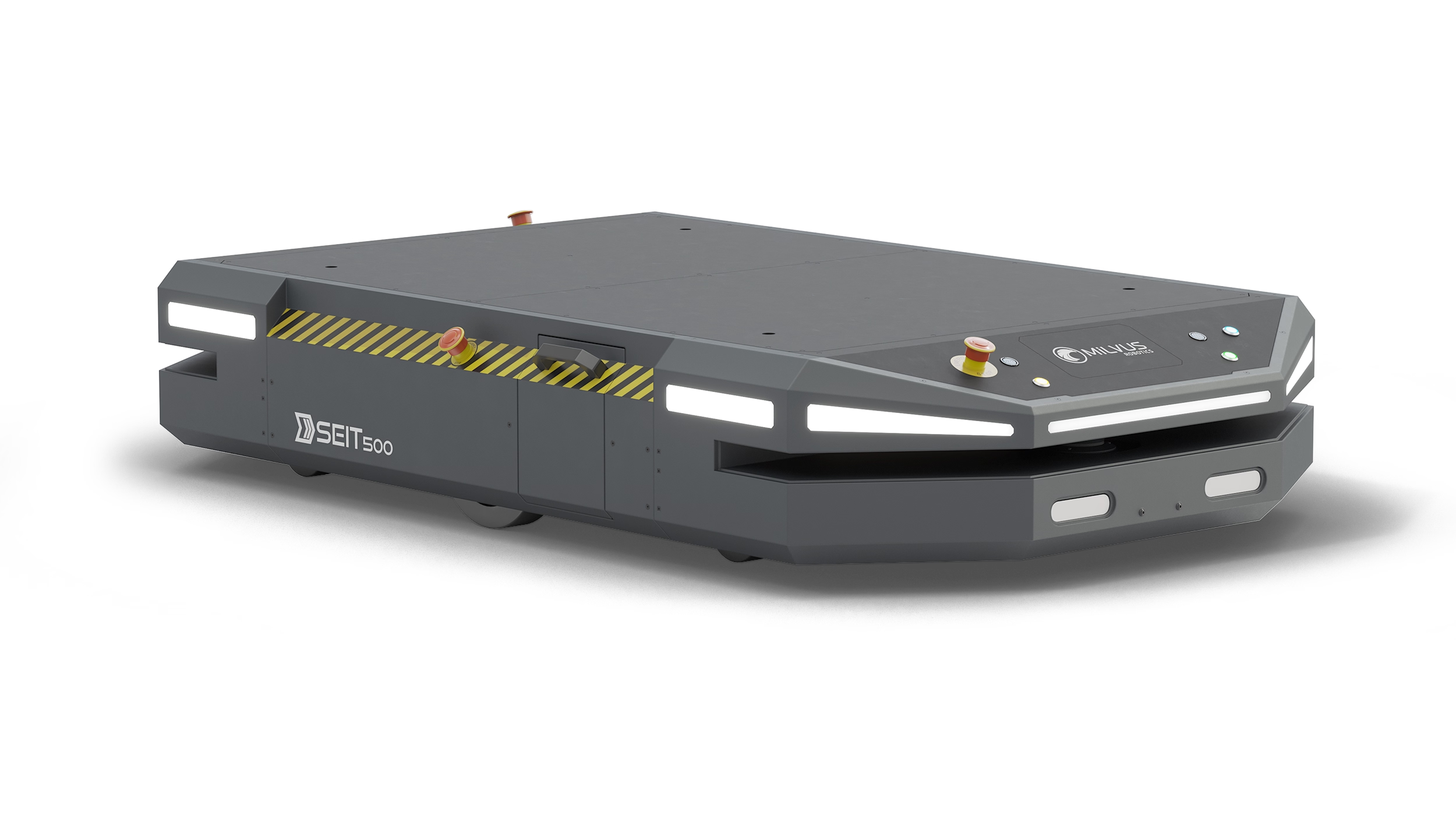

When you think of integrating robots, you might first think of how robotic intelligence can improve your operation. But you can also benefit from some robotic muscle! For example, our SEIT Autonomous Mobile Robots have the ability to move materials in your warehouse, protecting your employees from injuries and freeing them up for more complex tasks.

Not only is this good news for your employees who can finally take a rest from all the heavy lifting, but it’s also good news for your bottom line. You won’t have to worry about employees being out for injuries as frequently and you won’t have to pay workers comp or employee medical bills.

Preventing the Spread of Infectious Diseases

Robots aren’t just great at preventing injuries. They can also help you prevent illnesses from spreading on the job. This is more valuable today than ever before due to the COVID-19 pandemic. Autonomous robots reduce person-to-person contact at work. Fewer employees are needed to complete tasks such as inspecting machinery and moving materials. This promotes social distancing and a safer work environment.

Once again, protecting your employees from sickness is another way to help your bottom line. It reduces the sick days your employees have to take. It also ensures your operation gets maximum uptime at a time when many plants must shut down if they experience a COVID outbreak in their facility.

Enhance Safety at Your Workplace with Autonomous Mobile Robots

If you want to maximize safety in your work environment, you need to start integrating more robots. Milvus Robotics has the solutions your business needs to reduce risks and keep everyone on staff healthy.

.avif)