AGV vs AMR: How to Choose The Right Technology?

Autonomous Mobile Robots

Automating your material handling is a smart way to optimize productivity. Both AGV and AMR technologies can accomplish similar tasks, but there’s a big difference between the two, and there is a clear choice for manufacturers that want to remain flexible, scalable, and future-proof. Here’s what you need to know about AGV vs AMR.

Automated Guided Vehicles (AGV)

Automated Guided Vehicles (AGVs) are unmanned electric vehicles that move materials around a facility. They travel on fixed paths, requiring infrastructure, and rely on pre-programmed software for instructions. While AGVs are a form of automation, they are not intelligent machines.

Autonomous Mobile Robots (AMR)

As the evolved version of AGVs, autonomous mobile robots, or AMRs, use perception and navigation algorithms to navigate facilities and move materials from one place to the next. They are not limited to a specific route.

Why AMRs Are More Sophisticated than AGVs

AMR technology is more sophisticated than AGV technology in several ways. Here’s what makes AMR the smart solution for today’s factories and warehouses:

Intelligent navigation

Instead of having a fixed route and a need for infrastructure, AMRs navigate using internal maps. The robot can calculate the most direct path in order to pick up and drop off parts, even in the presence of obstacles. With intelligent learning capabilities, they can take optimal paths in even the most unpredictable environments. Your material flow will remain on schedule and you won’t have to invest in expensive infrastructure.

Operational flexibility and scalability

Thanks to its intelligent navigation capabilities, AMR offers a high level of flexibility. Its route is not limited by wires, magnetic strips, or sensors like an AGV would be. AMRs are redeployable, so you can move them to different areas and easily set them up in their new location. As your business expands, it is easy to scale your AMRs as well.

Cost-effectiveness

AMRs may be technologically advanced, but they are still a cost-effective solution. They are quick and easy to deploy and do not require downtime during their setup. You can expect a return on investment in as little as six months or less. Scaling your AMR system requires minimal additional costs and no additional infrastructure.

Future-proofing for agile businesses

Today’s manufacturing businesses must be agile in order to remain competitive. Thanks to the flexibility, scalability, and cost-effectiveness of AMR technology, it is easier for your business to remain agile far into the future. With AMRs, you can easily implement changes in distribution layouts and production lines. As your business shifts and changes, your AMR technology can keep up.

While they were once the best way to automate material transport, AGVs are now an outdated technology. AMR technology has surpassed the capabilities of AGV and is the clear choice for businesses that want to remain competitive in a fast-changing world.

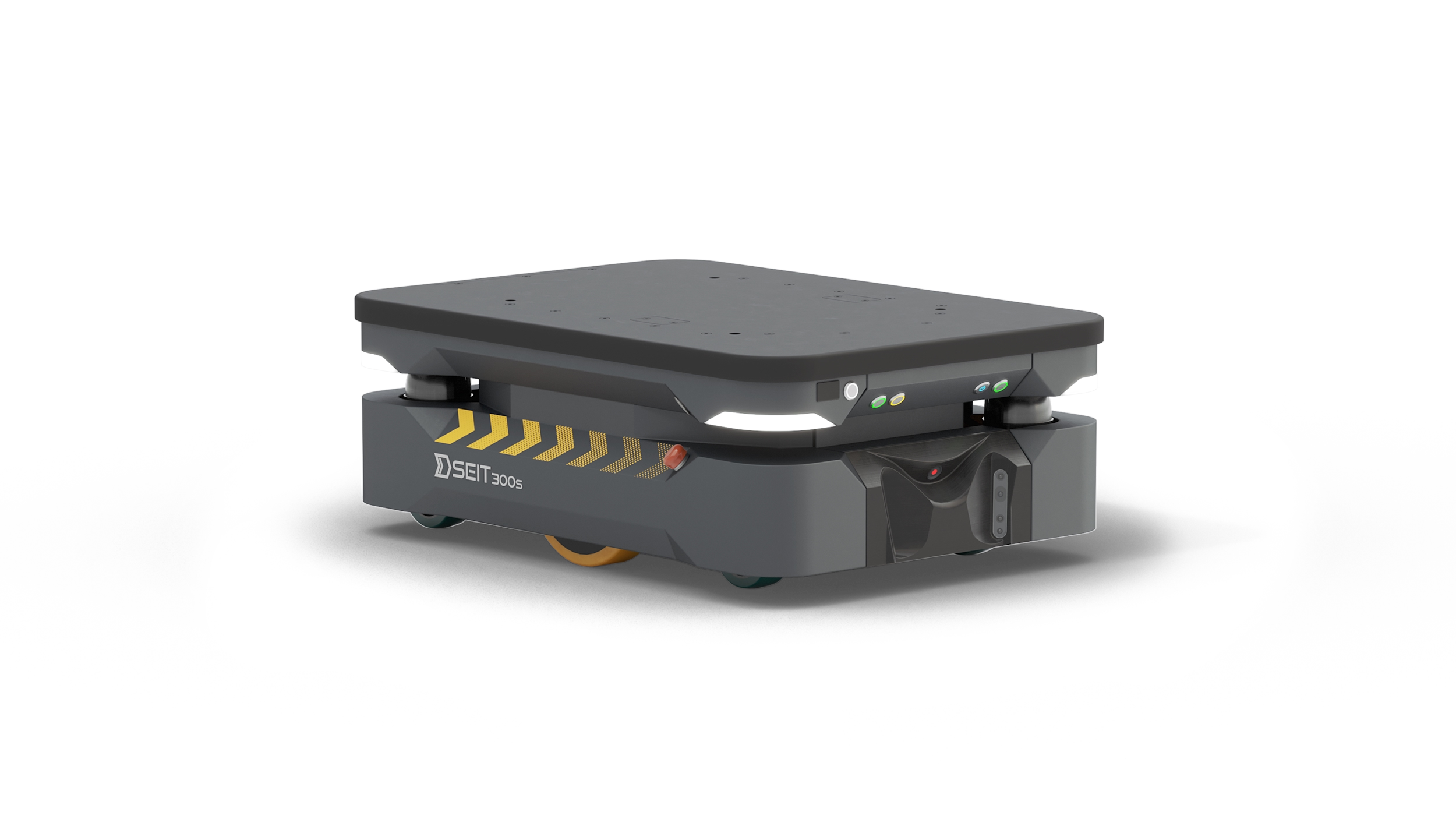

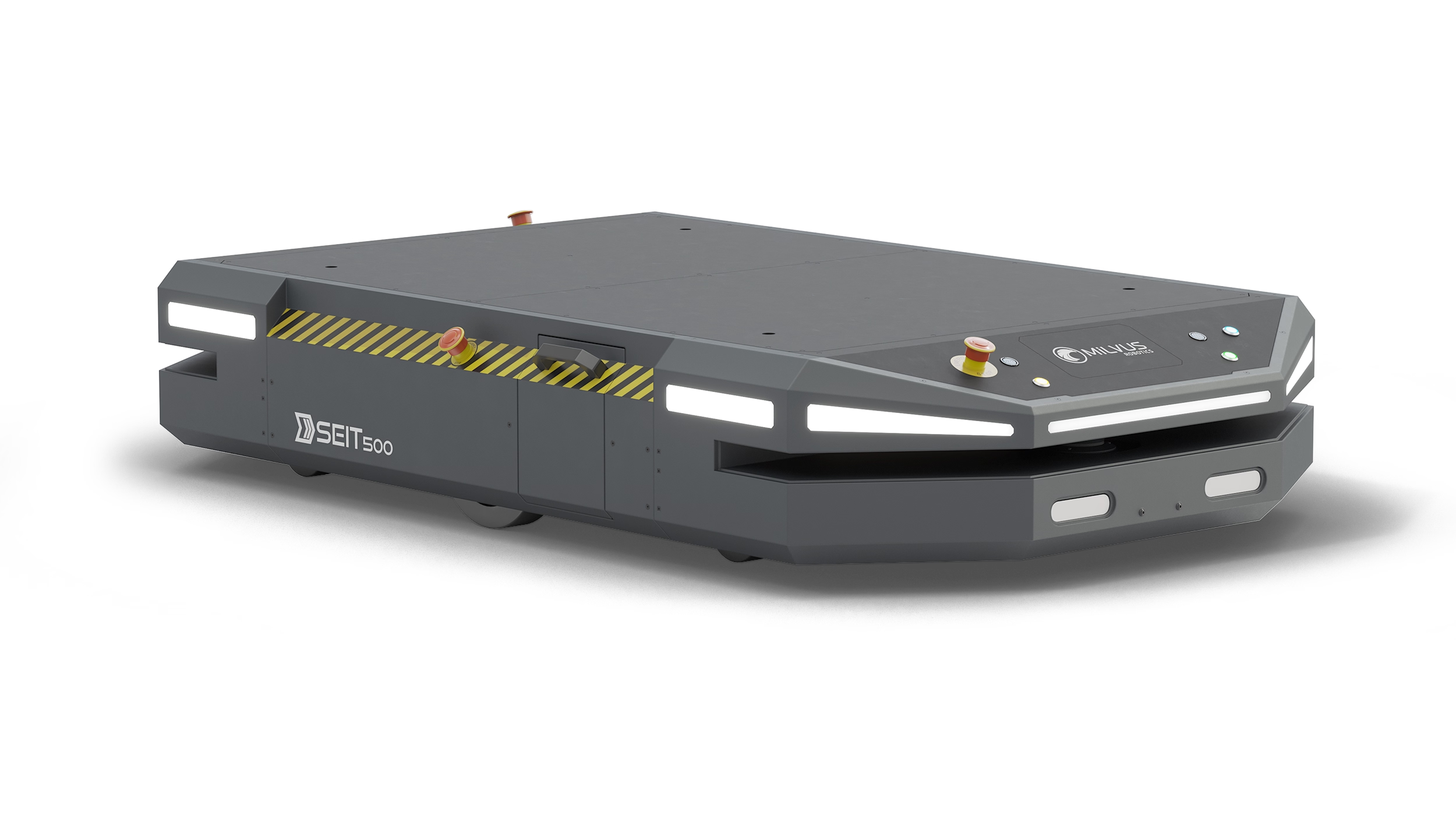

Are you searching for a cost-effective way to automate materials transport within your factories or warehouses? SEIT AMR is the fully-autonomous, collaborative solution. Learn more about how SEIT AMR can become your new hardest worker!

.avif)